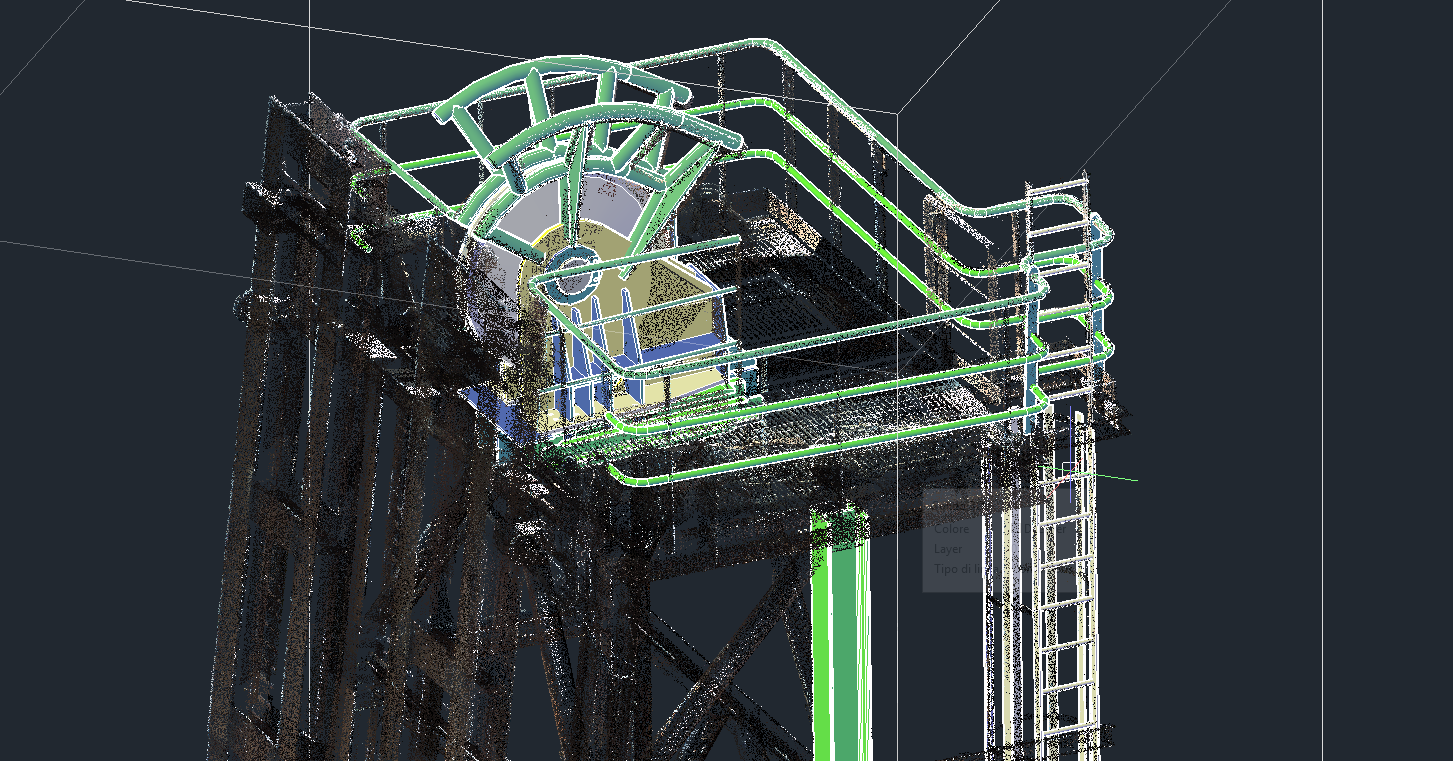

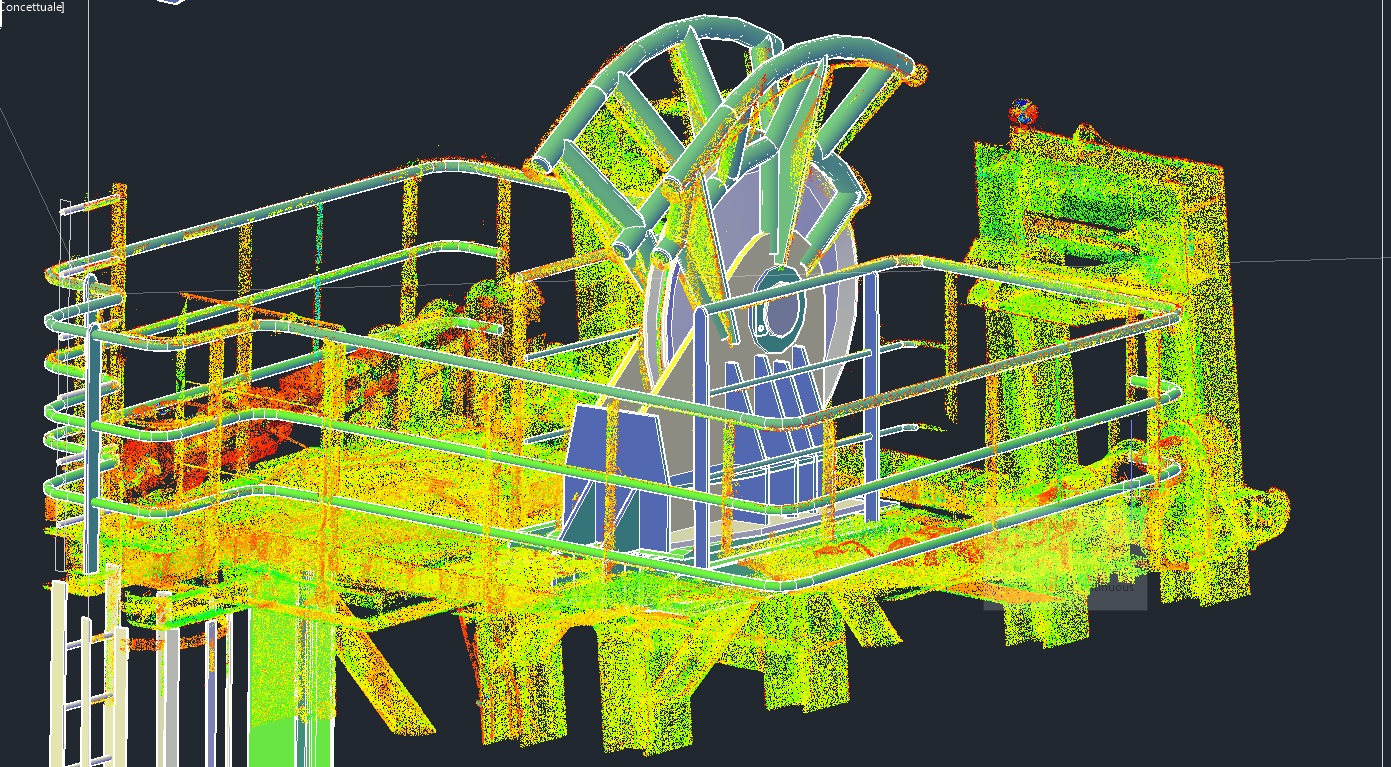

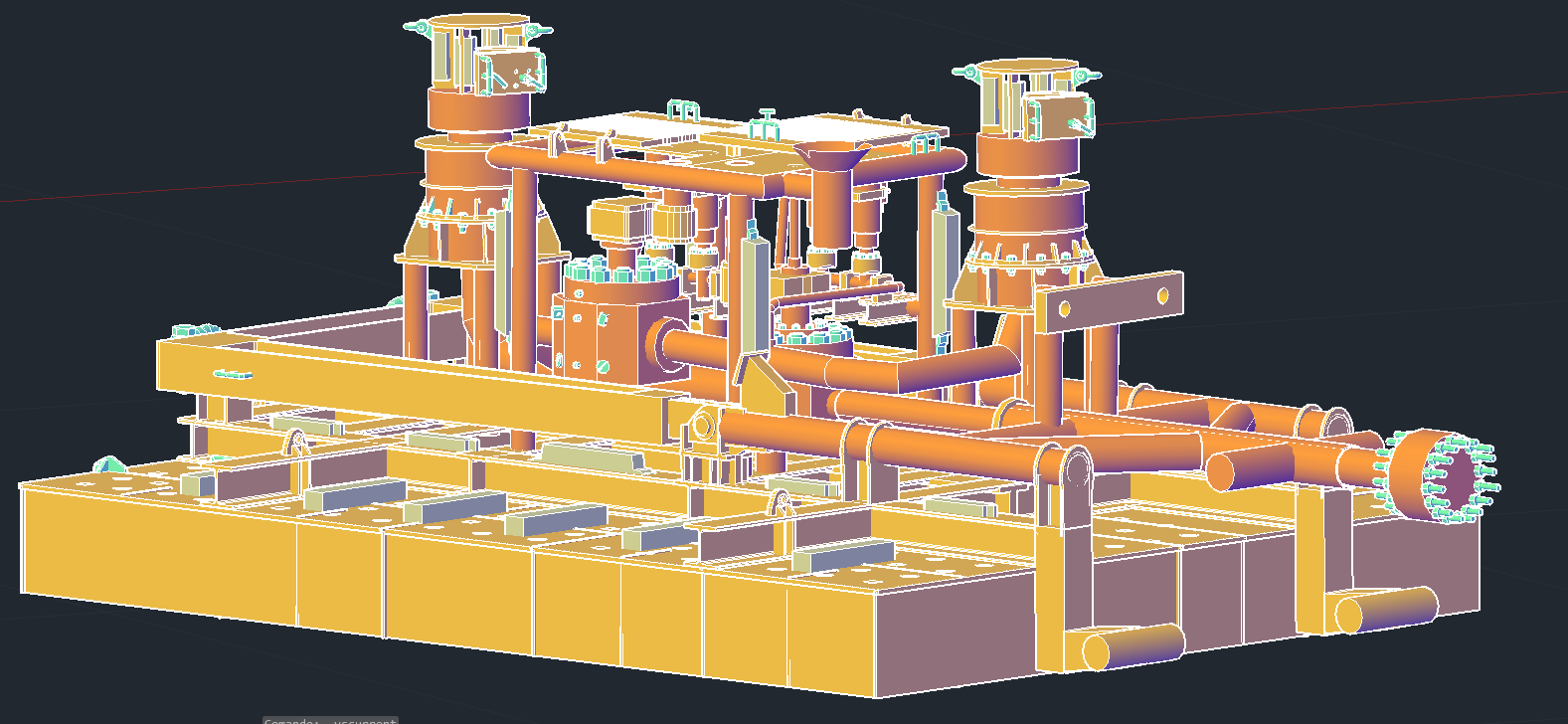

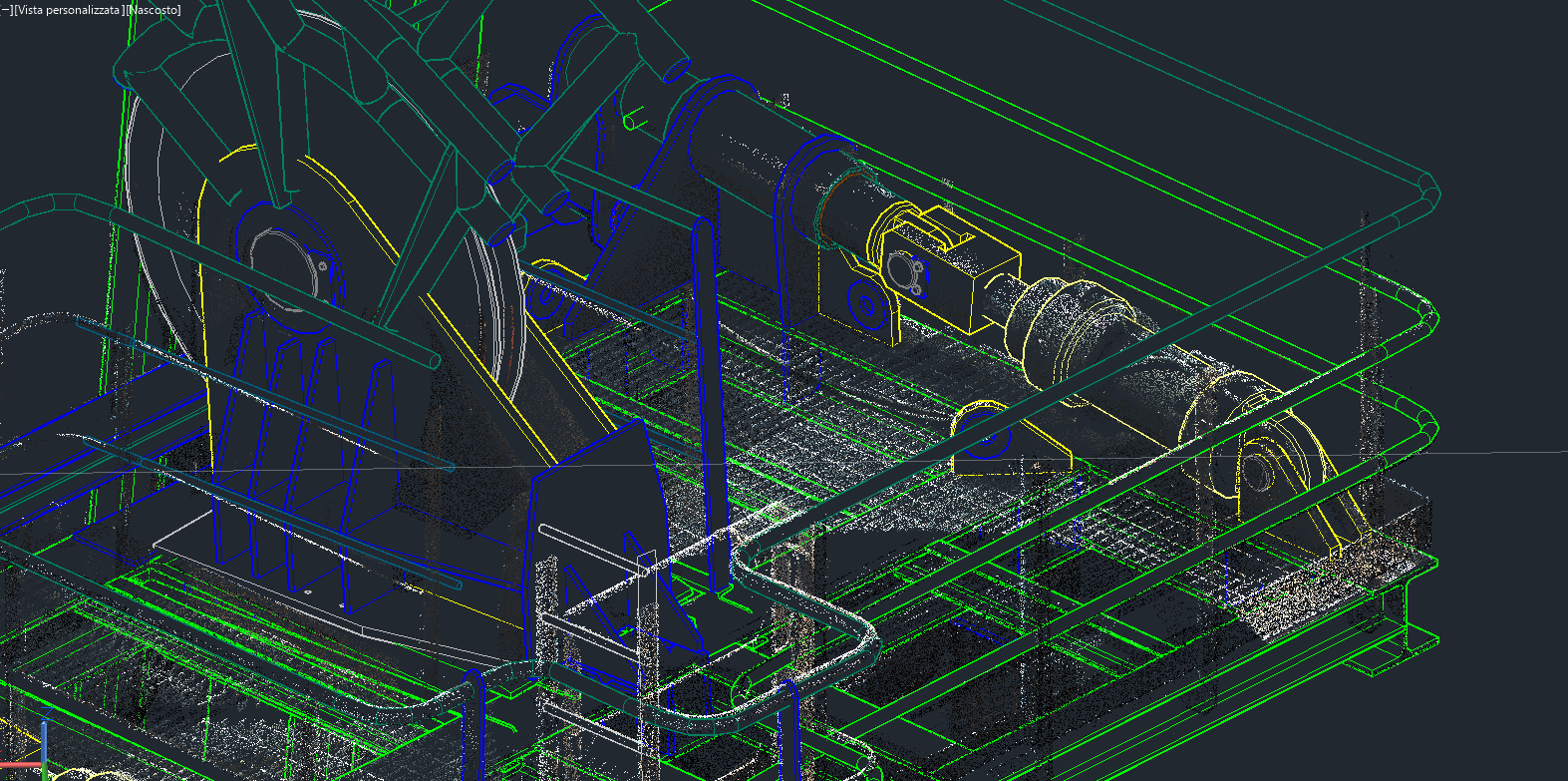

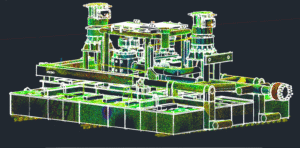

In the context of industrial plants, the accuracy of information is a crucial element to guarantee safety, operational efficiency and the success of each design phase. For these reasons, 3D surveys are today an essential tool to acquire precise and complete data of the existing environment, overcoming the limits of traditional techniques.

From checking for interference to designing new production lines, through checking for deformations or studying spaces, 3D surveys adapt to every industrial need, bringing concrete and measurable innovation to processes.

Advantages for industry

- Millimeter accuracy: essential for designing revamping, maintenance or expansions.

- Reduction of plant downtime: surveys are performed quickly and with minimal interference on production activities.

- Complete documentation: a “digital twin” of the plant is obtained, also useful for inspections, predictive maintenance and training.

- Safety: even hard-to-reach areas can be detected, reducing risks for technical personnel.